Shared-Edge-Thermoforming

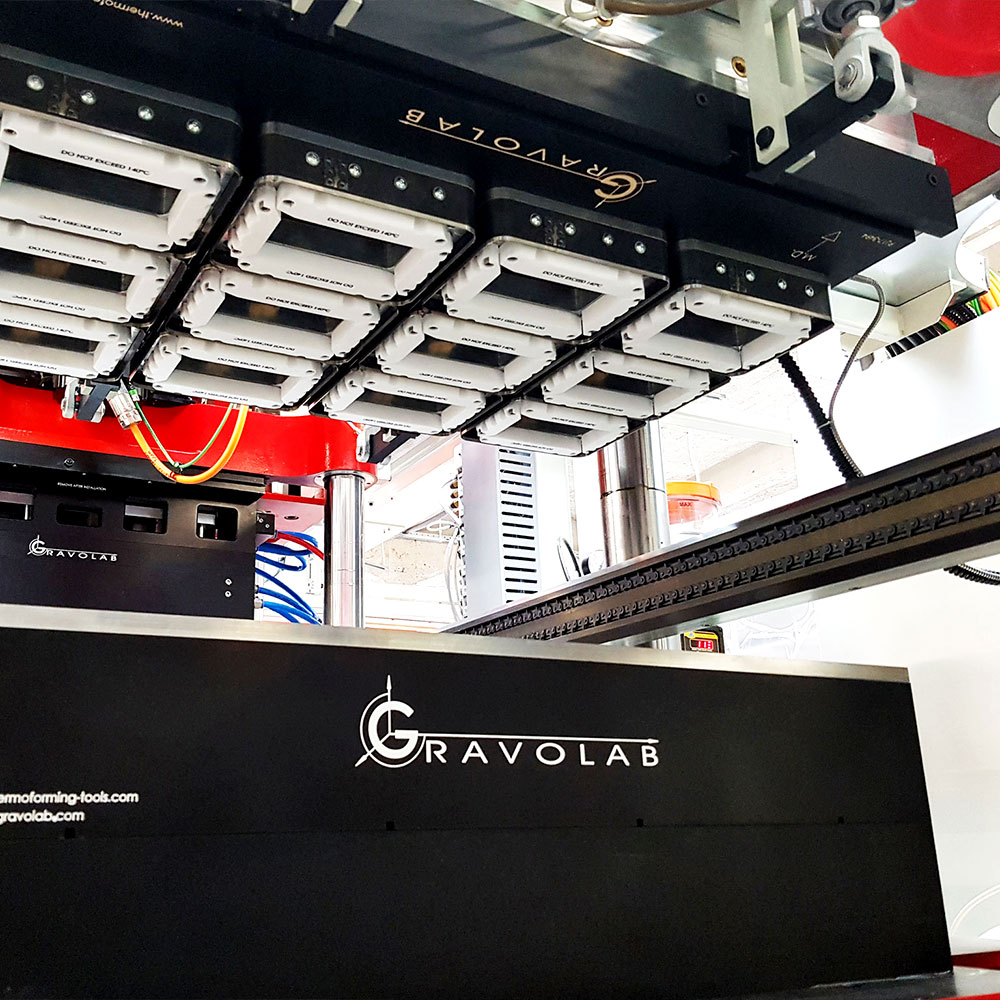

For over 15 years, GravoLAB produces the most efficient thermoforming tools for single use plastic packaging in the world. All our efforts are focused on reducing the usage of raw material for the same output. From South America, US, Europe and Russia, our toolings are making the difference, each day producing packaging in a responsible way.

…wondering What is

Shared-Edge-Thermoforming?

Shared-Edge-Thermoforming means that two adjacent parts with straight sides, are not separated by a web like we normally see on a conventional tool, but they are connected together during thermoforming process. The goal is to reduce the size of the web to zero, therefore reduce the material usage. For toolings running on radiant-heat machines, there are limitations caused by increased complexity, cooling restrictions in decreased space, reduced mechanical support for extreme cutting forces, stability over tens of millions of cycles, and Shared-Edge-Thermoforming seems IMPOSSIBLE.

We made Efficient Thermoforming POSSIBLE!

GravoLAB toolings help you to reduce CO2 footprint, therefore protect the environment.